Well Water Filtration Fundamentals Explained

Table of ContentsSome Of Well Water Filtration9 Simple Techniques For Well Water FiltrationThe Best Strategy To Use For Well Water FiltrationFascination About Well Water Filtration

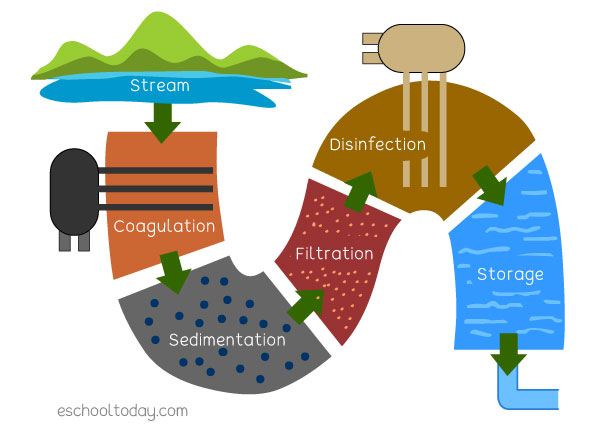

Pathogenic microorganisms are the microscopic in the water that can cause waterborne conditions such as gastroenteritis, typhoid, dysentery, cholera, and also giardiasis (well water filtration). Tip 5 Filtration, The chlorinated settled water then moves right into the Filtration Facility as well as onto the filters for the last of the significant unit processes utilized to deal with the alcohol consumption water.

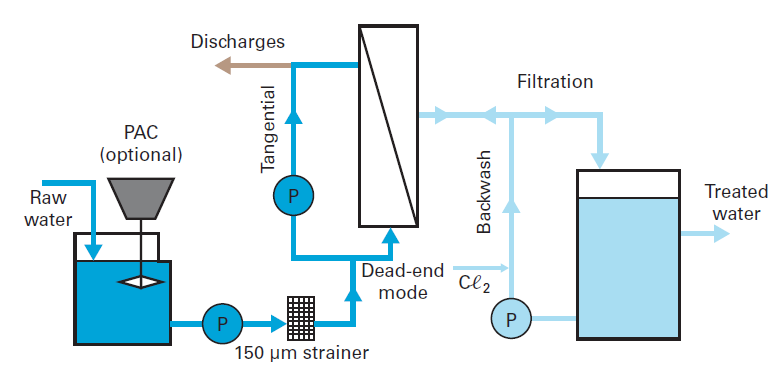

When the filters start to get jam-packed loaded with bits, the operators clean them utilizing a treatment called. Drinkable water is run backwards with the filters releasing the entrapped particulates that are gathered in drainpipe troughs. The backwash water is sent to the Backwash Recovery Pond and also, after a working out process, the backwash water is gone back to the raw water settling pond for re-use.

Before the water leaves the clearwells under the water therapy plant chlorine is included a 2nd time for post-disinfection. The added chlorine makes sure that the water stays safe to consume alcohol also at the furthest reaches of the circulation system. In enhancement to the chlorine, fluoride is included in our drinking water at the plant.

How Well Water Filtration can Save You Time, Stress, and Money.

The USA Public Health Solution has actually determined the maximum focus for fluoride in United States water to be in the series of 0. 7 to 1 - well water filtration. 2 components per million. Liquified fluoride-containing minerals are gauged year-round in the water of the Arkansas River. The natural fluoride content of the river water averages.

The water therapy plants enough fluoride to elevate that level to. 9 parts per million. The fluoride level is determined daily at the water treatment plant as well as regular monthly at the tap to make certain it suffices to meet the focus suggested by USA Public Health Service (USPHS) (well water filtration).

The water is examined daily for various criteria by our water plant operators as well as by constant on-line tracking by procedure instrumentation. Several of the water quality parameters kept track of and evaluated for are chlorine, turbidity, alkalinity, solidity, liquified oxygen, conductivity, and also p, H. Worths for specifications of the treated water change with the moment of year.

Coagulation When water gets in a treatment plant, the initial stage while doing so is coagulation where chemicals are included to the water system to allow microparticles and also small solids to stick with each other. Polyelectrolyte, ferrous sulfate, and light weight aluminum sulfate are instances of chemicals used in the water treatment plant process to aid coagulation.

Well Water Filtration Things To Know Before You Get This

Quality requirements additionally need to be met as part of the governing procedures within water therapy plants. This includes normal upkeep of the system by certified engineers. Flocculation As soon as water has been treated with the coagulation chemicals it enters a container with gigantic paddles. These mix the chemicals as well as water together and also make it possible for the mini particles to form right into larger pieces that are most likely to stick, making the sedimentation process in water therapy much more effective.

During this final stage water is passed with a filter in a regulated fashion. Any kind of bits adhere to the filter, leaving clean water to why not try this out be piped right into the municipal supply. Pumping stations pump water to domestic customers utilizing pipelines. Last Ideas on The Refine of Water Filtration in Water Plants The water filtration plant processes are vital to maintaining a secure supply of water for public and also commercial usage.

Industrial water treatment systems fulfill a selection of filtration as well as splitting up needs. They can range from fairly portable and also simple to complicated, multiunit procedures that serve a range of applications. If you're brand-new to water treatment, you could be asking Considering that industrial water treatment is a facility family members of modern technologies as well as systems, this article helpful site will concentrate on offering a high-level summary of the innovations that are commonly used as well as sum up how they work, aiding you to better understand the very best possible solutions for your facility.

Some Known Questions About Well Water Filtration.

That claimed, each system will vary relying on the facility's demands as well as a number of the modern technologies that compose these systems can be comparable. Generally, some of the most-needed industrial water therapy systems typically consist of: Raw water treatment systems Central heating boiler feed water therapy systems Cooling down tower water therapy systems Wastewater therapy systems The innovations chosen as well as in what order they appear in each water treatment system will vary relying on the pollutants that require to be gotten rid of, however it is possible to limit what you may see in these 4 typical commercial treatment systems.

Finally, the stream is infiltrated a gravity sand filter to catch any kind of little fragments that did not settle out. If organic contamination and/or water potability is an issue, the water may then be sanitized to remove any type of microorganisms. Sanitation may be accomplished with the application of chemical disinfectants (e.

In IX conditioning, a stream is directed through a strong acid cation material that is "charged" with sodium; as the water flows via, the resin records the hardness-causing calcium or magnesium ions, while releasing the salt ions into the stream. Adhering to treatment, the water is pumped or otherwise routed for usage in other places in the facility.